McDonald's Quality Story

Our strict standard is what takes to make our burgers taste even better!

Fresh ingredients raised with care and effort of everyone make up a delicious McDonald’s burger.

From the farm to the restaurant

Raw materials preparation and processing

Our raw material suppliers manage supply and processing based on a strict standard to prepare good quality materials.

Beef

100% beef patties originated from the clean regions of Australia, free of preservative & additive

McDonald's beef patties are made of 100% beef raised in the clean nature of Australia, with no additives and preservatives.

We manage the whole procedure from production to distribution through “beef traceability number” and are fully committed to using only the best quality beef to meet our food safety standard.

Beef traceability number: A number that provides detailed information of beef products (butchery of export country, processing location, export supplier and slaughterhouse, kill date, date of import) at the imported beef supply history management website

In case of any unavoidable situation, the origin of beef may change temporarily.

Chicken

Chicken patties made with safe and fresh ingredients that are carefully selected

McDonald's Chicken patties use safe ingredients with no antibiotics or preservatives listed on the HPCIA(High Priority Critically Important Antimicrobials) defined by WHO.

Also, our chicken patties are produced in butcheries that strictly comply with McDonald’s Animal Health & Welfare Standards and HACCP & FSSC22000 certified facilities.

HPCIA (High Priority Critically Important Antimicrobials): Antibiotics that are prescribed for human use only. When used in animals, it may have impact to people who have eaten them.

Buns

Freshly baked buns delivered everyday

McDonald’s buns are high-quality products that are produced at a GFSI*-certified plant with 60 years of expertise.

We only use freshly-baked buns made everyday in local plants according to daily demand projection. The buns are kept fresh until they are delivered to each restaurant by using a dedicated truck that protects the products from contaminants.

GFSI (Global Food Safety Initiative): International food safety association established to provide consistent improvement of the food safety management system for securing safe food supply to consumers.

The burger buns used at McDonald’s are manufactured in a GFSI-authorized factory that has been certified with the food safety management system (FSSC-22000).

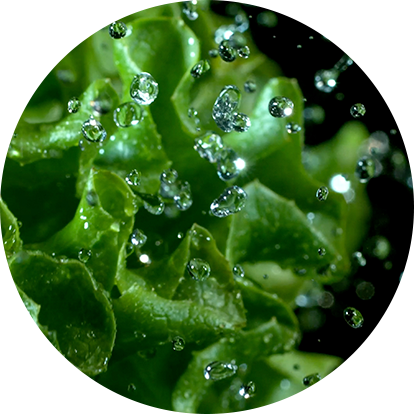

Lettuce

Fresh lettuce supplied by a manufacturer that is certified in global produce quality management

McDonald’s strictly monitors the farming conditions of lettuce such as clean water for farmlands, rich nutrients of soil and any sign of contaminants near the farm.

Once harvested, the lettuce is thoroughly washed, vacuum-packed for freshness after sterilization processes, and delivered to the Delivery Center within 2 days from processing.

Global produce quality management certification: A standard regarding the reliability of the agricultural products by controlling hazardous factors under a certain allowable level from production to product packaging. The controlled factors include water, soil, agricultural pesticide, fertilizer, heavy metal and microbe.

In case any unavoidable situation such as natural disasters occurs, the lettuce supplier may change.

tomatoes

100% locally-sourced tomatoes grown with care

McDonald’s tomatoes are grown and harvested from our fertile farmland filled with rich soil.

Once harvested, all tomatoes are thoroughly washed for food safety and delivered fresh after sterilization process.

eggs

High-Quality 1+ grade local eggs

McDonald’s eggs are treated with the strictest sanitary process including surface cleaning and sterilization process.

They are refrigerated at the temperature of 7°C or lower for its best condition until they are finally cooked at our restaurants.

In case any unavoidable situation such as natural disasters occurs, the lettuce supplier may change.

cheese

Rich-flavored natural cheese from New Zealand

McDonald's cheeses are made with milk from dairy cattle that graze in the clean grassland of New Zealand, delivering the rich and savory taste of natural cheese.

onion

Fresh onion supplied by HACCP certified facilities

McDonald’s onions go through strict sterilization and washing process in the best hygienic facility and are vacuum-packed to be delivered safe and fresh.

Ingredients storage to delivery

Storage and delivery are as important as fresh ingredient preparation and processing, right?

Shipping companies inspect the product quality meticulously and store products safely to keep ingredients’ freshness and safety.

Restaurants' commitment

How are the ingredients that have arrived at the restaurants managed?

"From ingredient deilvery to serving, McDonald’s never gets complacent."